Blast Cleaning

Cincinnati Steel Treating offers a wide variety of blast cleaning services for multiple types of parts including shot blasting for large parts, tumble blasting for small parts, and glass bead blasting for specialty finishes. CST can perform blast-only services on a commercial basis, or we can offer blast cleaning as a finishing touch on parts that we have heat-treated. Ask one of our process engineers for the best blast process to use to provide the ideal surface finish for a part.

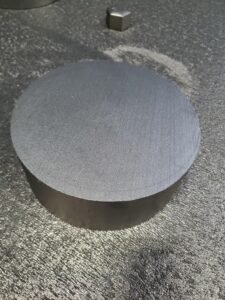

Metal Part before blasting

Metal Part After Blasting

Trust your Blast Cleaning Needs to our Experts

Cincinnati Steel Treating Blast Capabilities

Cincinnati Steel Treating (CST) has a large shot blast table that measures 96” in diameter and can hold parts up to 36” in height. The table is capable of holding 5,000 pounds. A tumble blast unit is also available that can blast clean parts one at a time that are up to 36” tall and 18” in width. The tumble blast can handle four parts at once with a weight limitation of 50 pounds per part, or 200 pounds per

Applications of Shot Blasting

Shot Blasting has been performed by Cincinnati Steel Treating on parts that are destined for the food processing industry, military applications where the type of blast medium and the degree of surface finish are specified, and for large forgings that are machined after heat treat into gears, shafts, or other power transmission components. CST has experience in blast cleaning a wide variety of materials. We

Shot Blasting/Blast Cleaning– How it works

Shot blasting is a process where hardened shot is propelled at high velocity against the surface of a heat-treated part. The shot can be composed of many different types of material, but we choose to use only steel shot to avoid damaging semi-finished parts. An even more delicate form of blast cleaning comes in the form of glass beads that deflect off the surface before deforming it. All of these various

Bring Us Your Blast Cleaning Challenges

For over 80 years, we’ve helped our clients across many industries improve production time and parts performance, quickly and efficiently. Turnaround times are fast and quality control is precise. As your outsourcing partner, we provide solutions to take your results to the next level.